Linee automatiche di riempimento

Abbiamo una lunga esperienza nella progettazione di linee automatiche su misura per ogni settore, che sia alimentare, chimico, farmaceutico o cosmetico.

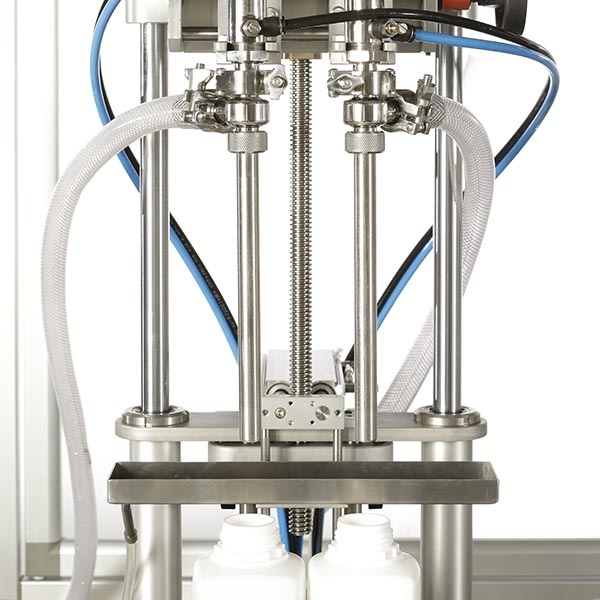

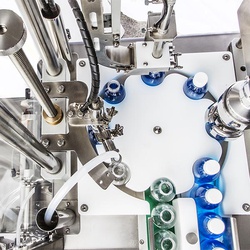

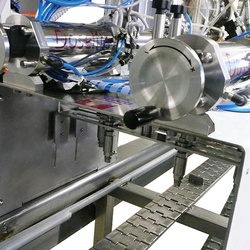

Progettiamo linee automatiche di riempimento, tappatura, etichettatura, dosaggio per un'ampia gamma di prodotti liquidi dei settori alimentare al chimico, dal cosmetico e al farmaceutico.

Nel corso degli anni abbiamo acquisito una vasta esperienza in quest'ambito e realizziamo prodotti robusti, affidabili e costruiti su misura in base alle specifiche esigenze produttive del cliente.

Contattaci spiegando quali sono le tue esigenze, ti consiglieremo il sistema più adatto.