Tappatrice pneumatica

Una tappatrice da banco pensata per chiudere in tutta semplicità tappi twist-off e tappi in plastica a vite su barattoli, vasetti e flaconi di ogni tipo.

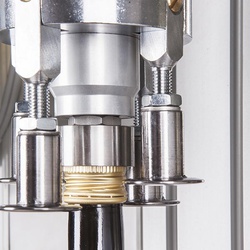

Tappatore pneumatico da banco per capsule twist off o in plastica a vite.

Basamento in acciaio inox.

Regolazione manuale dell’altezza della testa di tappatura mediante volantino e relativo contatore che fornisce un riferimento in base al contenitore da tappare.

Altezza massima del contenitore 330 mm. Regolazione della pressione verticale effettuata sulla capsula, della coppia di torsione (fino a 11 Nm) e della velocità di rotazione del mandrino a seconda delle esigenze.

Sistema regolabile di blocco vaso mediante pistone pneumatico. Il mandrino magnetico per capsule twist off è realizzato sul diametro della capsula.

L’operatore colloca la capsula al suo interno ed effettua le regolazioni in base alle dimensioni del contenitore e della capsula da trattare; premendo i due pulsanti ai lati del basamento la macchina effettua la chiusura in pochi secondi.

Caratteristiche tecniche

| Tappatrice pneumatica | |

|---|---|

| Produzione | ~ 500/600 bottiglie/ora |

| Peso | 30 Kg |

| Consumo | circa 150 aria libera/min |

| Pressione aria | 3-5-7 bar |

| Potenza | 0,15 Hp 0,35 Hp 0,53 Hp |

| Velocità rotazione | 500 rpm 565 rpm 630 rpm |

| Coppia massima | 4,2 Nm 8,4 Nm 11 Nm |