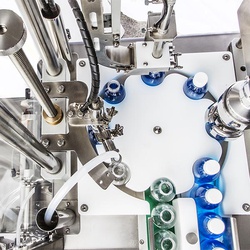

Dosatore volumetrico Doselite

Dosatore da banco completamente personalizzabile per dosare liquidi, creme e ogni prodotti denso o semi-denso.

Doselite è un dosatore pneumatico per dosare piccole quantità di prodotto con precisione. La macchina consente di confezionare prodotti alimentari, chimici cosmetici o farmaceutici — anche di notevole densità e con pezzi in sospensione — in vasetti, barattoli o flaconi in plastica, vetro o qualsiasi altro materiale.

Le dosi erogabili vanno da 0 a 1300 ml a seconda del modello di Doselite. Le regolazioni possibili permettono di adeguare le prestazioni della macchina al prodotto e ai flaconi da dosare.

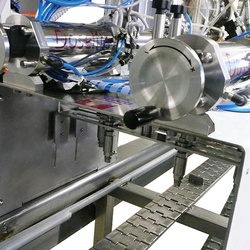

Doselite funziona tramite aria compressa e non ha bisogno di energia elettrica o pompe esterne che spingano il prodotto. I nostri dosatori sono progettati e costruiti con estrema cura, predisposti per funzionare senza interruzioni da soli o inseriti come pompe di dosaggio all'interno di linee automatiche. In alternativa, il funzionamento della macchina può essere elettronico. In questo caso, la macchina diventa un dosatore elettronico per liquidi.

A seconda della viscosità e tipologia del prodotto da riempire, Doselite può essere personalizzata con un'ampia gamma di componenti:

- valvole dosatrici per liquidi, ideali per imbottigliare prodotti come olii essenziali, soluzioni alcoliche e liquide in generale

- valvole per il dosaggio di prodotti densi anche con pezzi in sospensione come ragù, salse, paté, creme, paste dense

- valvole antigoccia per il dosaggio di prodotti a caldo molto viscosi o appiccicosi come miele, colla e prodotti simili

- beccucci erogatori per prodotti liquidi o densi, con o senza dispositivo antigoccia

- tramogge di alimentazione prodottoeventualmente personalizzate con mescolatore gruppo riscaldante dispositivi di pressatura per prodotti particolarmente pastosi

In questo modo Doselite può distribuire con estrema precisione prodotti di ogni composizione, densità e viscosità.

Tutte le componenti sono fatte per essere smontate e pulite facilmente e senza bisogno di utensili.

Massima precisione

- La quantità di prodotto da erogare viene emessa con precisione costante. Le valvole antigoccia e i beccucci erogatori evitano sgocciolamenti, anche con prodotti molto viscosi tipo miele, ragù o colla.

Semplicità d'uso

- Doselite ha due modalità di funzionamento:

- automatico: fuoriuscita automatica del prodotto a intervalli regolari

- manuale: il prodotto viene dosato premendo un pedale comandato dall'operatore

Ampia gamma di regolazioni

- pressione

- velocità di erogazione

- velocità di aspirazione

- funzionamento manuale o automatico

Materiali di qualità

- Tutte le parti che entrano in contatto con il prodotto sono costruite in acciaio inox AISI 316. Per questo motivo il dosatore Doselite è flessibile e può operare in qualsiasi settore, alimentare o chimico-farmaceutico.

Funzionamento pneumatico o elettronico

- La macchina può essere fornita sia con funzionamento pneumatico che elettronico. In quest'ultimo caso diventa un vero e proprio dosatore elettronico per liquidi.

Caratteristiche tecniche

| Dosatore volumetrico Doselite | |

|---|---|

| Dosi erogabili | 0 - 38 ml 2 - 100 ml 5 - 250 ml 5 - 380 ml 20 - 680 ml 50 - 1300 ml |